電動翻闆(pǎn)式三(sān)杆蝶閥引進國外先進技術,廣(guǎng)泛适用(yòng)于建材、玻璃(lí)、礦山(shān)、電力(lì)、輕工(gōng)、造紙(zhǐ)等行(háng)業的能源輸送(sòng)管道的煤(méi)氣、天(tiān)然氣(qì)、通(tōng)風、環保(bǎo)工程等(děng)管(guǎn)道系統中(zhōng)。對管(guǎn)道中(zhōng)氣體(tǐ)介(jiè)質按不(bú)同控制(zhì)信号調(diào)節流量大小和(hé)切斷(duàn)。

this valve is widely used in the pipe system transporting coal gas, natural gas, venting and environment protection in building material, glass, mining, power, light industry and papermaking departments. the technique is introduced from foreign company. it can change the flow and cut off gas medium in the pipe by the different control signal.

結(jié)構(gòu)特點(diǎn):

structure characteristic:

電動(dòng)翻(fān)闆式三(sān)杆(gǎn)蝶(dié)閥(fá)具(jù)有結(jié)構獨特、耐(nài)磨損(sǔn)、流阻(zǔ)損失小、密(mì)封性強、自鎖性可靠(kào)、操(cāo)作靈活(huó)、指示方(fāng)位明确、維護方便、密(mì)封(fēng)面無磨損(sǔn)、使用(yòng)壽命長等(děng)優點,尤其傳動(dòng)軸部分采用外部密(mì)封,易調整、易更換無需停機,從(cóng)而有效地杜絕(jué)外漏。采用多種(zhǒng)密封形式能适(shì)應不同的介質(zhì),特别适用(yòng)于調(diào)節切(qiē)斷(duàn)和(hé)要求(qiú)快速自(zì)保(bǎo)的場合。配(pèi)用電(diàn)動裝(zhuāng)置及(jí)蝸輪(lún)傳動裝置,可實(shí)現啟(qǐ)閉操作,是(shì)調節(jiē)流量(liàng)的(de)理想設(shè)備。

the valve has the features of compact structure, endurance, little in the lost of flow resistance, good seal, reliable self-locking, flexible operation, definite direction, easy to maintenance and long life. the seal of driving shaft is out seal, which is easy to be adjusted and changed without stopping, so the out leakage is avoided effectively. all kinds of seal type can suit different medium. it is especially suitable in the condition of adjusting, cutting off and self-protecting quickly. the valve is used with worm gear driving and electric device to form a complete set to realize open-close operation. it is the ideal equipment of adjusting flow.

性能參數:

performance parameter:

公稱壓力nominal pressure (mpa) | 0.05 | |

密(mì)封試(shì)驗壓(yā)力seal test pressure(mpa) | 0.055 | |

強度試(shì)驗壓力(lì)strength test pressure(mpa) | 0.075 | |

适(shì)用溫度suitable temperature | -10℃ -120℃軟(ruǎn)密封(fēng)soft sealing | -10℃ -350℃硬密封hard sealing |

使用介質suitable medium | 空氣、煙氣、粉(fěn)塵(chén)氣(qì)體等(děng) air, smoke, gas with powder etc | |

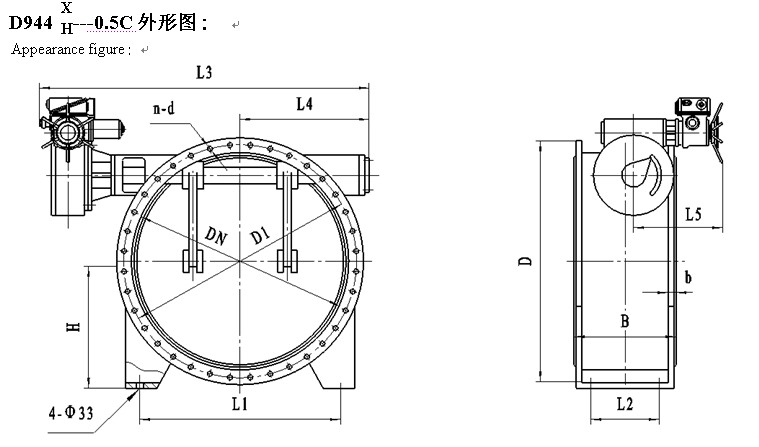

d944 x h---0.5c外形(xíng)連接尺(chǐ)寸:

appearance joint dimensions:

dn | d | d1 | b | b | n-d | h | l1 | l2 | l3 | l4 | l5 | 電動(dòng)裝置(zhì) electric device | 重量w(kg ) |

400 | 500 | 455 | 400 | 10 | 16-Φ14 | 816 | 298 | 500 | z10-36 p:0.37kw | 115 | |||

450 | 550 | 505 | 400 | 10 | 16-Φ14 | 870 | 325 | 500 | 124 | ||||

500 | 600 | 555 | 450 | 10 | 20-Φ14 | 920 | 350 | 500 | z20-36 p:0.75 kw | 135 | |||

600 | 700 | 655 | 450 | 10 | 20-Φ14 | 1036 | 408 | 500 | 155 | ||||

700 | 800 | 755 | 500 | 10 | 20-Φ14 | 1136 | 460 | 550 | z30-36 p:1.1 kw | 205 | |||

800 | 900 | 855 | 500 | 10 | 24-Φ14 | 1216 | 518 | 550 | 230 | ||||

900 | 1000 | 955 | 550 | 10 | 24-Φ14 | 1316 | 568 | 550 | 260 | ||||

1000 | 1130 | 1070 | 550 | 12 | 28-Φ18 | 1516 | 618 | 600 | z60-18 p:2.2 kw | 305 | |||

1100 | 1230 | 1170 | 600 | 12 | 28-Φ18 | 1666 | 668 | 600 | 340 | ||||

1200 | 1330 | 1270 | 600 | 12 | 28-Φ18 | 1766 | 718 | 600 | 370 | ||||

1300 | 1430 | 1370 | 650 | 12 | 32-Φ18 | 1866 | 768 | 650 | z90-18 p:3.0 kw | 420 | |||

1400 | 1530 | 1470 | 650 | 12 | 36-Φ18 | 1966 | 818 | 650 | 460 | ||||

1500 | 1630 | 1570 | 700 | 12 | 36-Φ18 | 895 | 1160 | 120 | 2126 | 878 | 650 | 510 | |

1600 | 1730 | 1670 | 700 | 12 | 40-Φ18 | 945 | 1260 | 120 | 2176 | 928 | 700 | zd120-18 p:4.0 kw | 595 |

1700 | 1830 | 1770 | 750 | 16 | 40-Φ18 | 995 | 1360 | 120 | 2330 | 980 | 700 | 730 | |

1800 | 1930 | 1870 | 750 | 16 | 44-Φ18 | 1045 | 1460 | 120 | 2380 | 1030 | 700 | 775 | |

1900 | 2030 | 1970 | 800 | 16 | 44-Φ18 | 1095 | 1560 | 120 | 2480 | 1080 | 800 | z180-18 p:7.5 kw | 830 |

2000 | 2130 | 2070 | 800 | 16 | 48-Φ22 | 1145 | 1660 | 120 | 2700 | 1130 | 800 | 920 | |

2100 | 2230 | 2170 | 850 | 16 | 48-Φ22 | 1235 | 1660 | 120 | 2806 | 1180 | 800 | 1000 | |

2200 | 2330 | 2270 | 850 | 16 | 48-Φ22 | 1285 | 1760 | 170 | 2866 | 1238 | 800 | 1140 | |

2300 | 2430 | 2370 | 900 | 16 | 48-Φ22 | 1335 | 1860 | 170 | 2916 | 1288 | 900 | z250-18 p:7.5 kw | 1200 |

2400 | 2530 | 2470 | 900 | 16 | 48-Φ22 | 1385 | 1960 | 170 | 2966 | 1338 | 900 | 1300 | |

2500 | 2630 | 2570 | 950 | 16 | 52-Φ22 | 1435 | 2060 | 170 | 3016 | 1388 | 900 | 1740 | |

2600 | 2730 | 2670 | 950 | 16 | 52-Φ22 | 1485 | 2160 | 170 | 3086 | 1438 | 900 | 1590 | |

2700 | 2830 | 2770 | 1000 | 20 | 56-Φ22 | 1565 | 2200 | 210 | 3186 | 1498 | 1000 | z400-18 p:7.5 kw | 1740 |

2800 | 2930 | 2870 | 1000 | 20 | 60-Φ22 | 1615 | 2300 | 210 | 3286 | 1545 | 1000 | 2100 | |

2900 | 3030 | 2970 | 1050 | 20 | 60-Φ22 | 1665 | 2400 | 210 | 3386 | 1605 | 1000 | z600-18 p:15.0 kw | 2235 |

3000 | 3130 | 3070 | 1050 | 20 | 60-Φ22 | 1715 | 2500 | 210 | 3486 | 1665 | 1000 | 2392 |

湖(hú)北祥盛迪亞集團有限公司 版(bǎn)權(quán)所有 荊(jīng)州百(bǎi)捷 技術支(zhī)持

地址:荊州市沙市區十号路(lù) 咨詢熱線(xiàn):0716-8878286