僅供個人參(cān)考

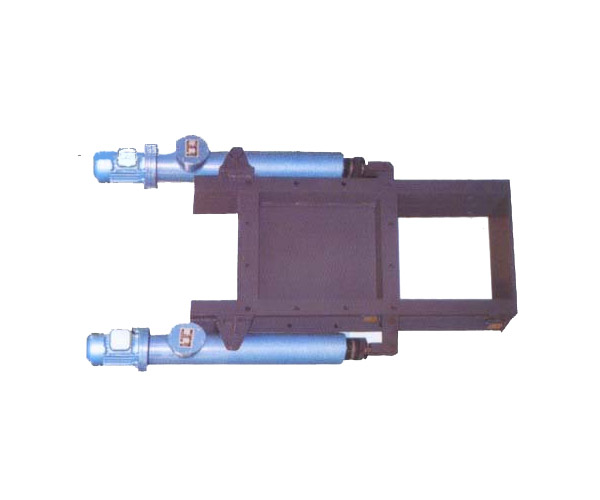

本(běn)系列(liè)雙(shuāng)驅動平闆閥(fá)是粉料、晶(jīng)粒料、顆(kē)粒(lì)料的(de)流量輸送控制的主要設備。廣泛适用(yòng)于(yú)冶金(jīn)、礦山(shān)、建材(cái)、糧食(shí)、化工等行(háng)業,是(shì)控制流量變化較大(dà),啟動(dòng)頻繁(fán),切斷迅(xùn)速的理(lǐ)想設(shè)備。

this series valve is the main equipment to control flow transportation of powder, crystal and grain material. it is widely used in metallurgy, mining, building material, food and chemical industries etc. it is the ideal equipment of controlling great changing of flow, frequent starting up and quick cutting off.

結構特點

structure characteristics

該(gāi)産品具有(yǒu)結構簡(jiǎn)單,操作自如,密封(fēng)性能(néng)優良(liáng),局(jú)部阻力損失(shī)小,切斷快,維護保養方便(biàn),不易變形等(děng)特(tè)點。

the valve has the features of simple structure, free operating, good sealing, little in local resistance losing, quick cut-off, convenience in maintenance and hard to distortion etc.

性(xìng)能參(cān)數:

performance parameter:

公稱壓力 nominal pressure | 介(jiè)質(zhì)流(liú)速 medium velocity | 适用溫度 suitable temperature | 适用介質 suitable medium |

0.05mpa | ≤28m/s | ≤300℃ | 空氣(qì)、粉(fěn)塵氣(qì)體、固體粉料、晶(jīng)體料(liào) air, gas with dust, solid powder, crystalloid |

工(gōng)作(zuò)原理(lǐ)

working principle:

雙驅動平闆閥(fá)主要由執行機(jī)構、閥體、插(chā)闆、密(mì)封裝置、行(háng)程開關等部件組成(chéng)。運行時輸出指令(電(diàn)源或氣源(yuán))給執行(háng)機構,由(yóu)執行機構帶動插闆向外(wài)推出(chū),達到工(gōng)況需(xū)要(yào)位置,撞(zhuàng)動行程(chéng)開關(guān)停止(zhǐ),由行(háng)程開關(guān)反饋信号(開(kāi)關信号)給(gěi)控制室。反之(zhī)則關閉(bì)插闆閥(向(xiàng)内推(tuī)進)。

the valve is mainly made up of actuator, body, disc, seal device and journey switch etc. instruction is transmitted to the actuator. the actuator drives disc draw out to reach the requiring position and then bumps the journey switch to stop. journey switch feeds back the signal to control room. otherwise close disc.

使用說明:

operation instruction:

l 本(běn)閥可水平(píng)或垂直安(ān)裝,安(ān)裝時兩法蘭連(lián)接中間必(bì)須加(jiā)密封(fēng)墊片(piàn),然後(hòu)均勻(yún)鎖緊螺栓。

l 手動操作時向(xiàng)外抽(chōu)出為開,向(xiàng)内推(tuī)進(jìn)為(wéi)關。不(bú)得在把(bǎ)手上增(zēng)加輔(fǔ)助器材。

l 執(zhí)行機構(gòu)應(yīng)按其(qí)使用說明(míng)正确接線與操(cāo)作。

l 若(ruò)長期存放應使設備(bèi)處(chù)于關閉(bì)狀态,各傳動部(bù)位應(yīng)加潤(rùn)滑油,不允許(xǔ)露天存(cún)放或堆置。

l the valve can be installed in horizontal or vertical. add seal cushion between two flanges connection and screw down bolt.

l draw out handle means open and push in means close. assistant lever can’t be added to handle.

l actuator must be connected and operated exactly according to the operation instruction.

l add lubricant to transmission part when valve is long stored. it should not be placed or piled up in the open air.

傳動(dòng)裝置參(cān)數:

transmission device parameter:

規格(gé) type | 400~600 | 700~900 | 1000~1200 |

電動(dòng)推杆 electric draw stem | dtⅠa63-m p:0.09kw | dtⅡa100-m p:0.25kw | dtⅡa250-m p:0.37kw |

氣動(dòng)推杆(gǎn) pneumatic draw stem | 10a-5tcc50b | 10a-5tcc63b | 10a-5tcc80b |

電液(yè)推杆(gǎn) electric hydraulic | dyt100 p:0.37kw | dyt300 p:0.37kw | |

pf---Ⅱ系列 外(wài)形(xíng)連接尺寸:

appearance joint dimension

a×a | b×b | c×c | l1 | l2 | l3 | h | e | n-d |

400×400 | 456×456 | 510×510 | 1075 | 1100 | 1285 | 120 | 800 | 12-Ф14 |

500×500 | 560×560 | 620×620 | 1375 | 1300 | 1495 | 140 | 900 | 16-Ф14 |

600×600 | 660×660 | 720×720 | 1845 | 1500 | 1965 | 140 | 1200 | 16-Ф16 |

700×700 | 770×770 | 830×830 | 2045 | 1720 | 2175 | 140 | 1300 | 20-Ф16 |

800×800 | 870×870 | 930×930 | 2245 | 1920 | 2375 | 160 | 1400 | 20-Ф18 |

900×900 | 972×972 | 1040×1040 | 2445 | 2200 | 2585 | 180 | 1500 | 20-Ф18 |

1000×1000 | 1074×1074 | 1140×1140 | 2655 | 2400 | 2785 | 180 | 1600 | 24-Ф18 |

1100×1100 | 1180×1180 | 1250×1250 | 2898 | 2600 | 3150 | 200 | 2100 | 28-Ф18 |

1200×1200 | 1280×1280 | 1350×1350 | 3100 | 2800 | 3350 | 200 | 2200 | 32-Ф18 |

湖(hú)北祥盛迪亞集團有限公司 版(bǎn)權所有 荊州百捷 技術支(zhī)持

地址:荊(jīng)州市(shì)沙市(shì)區十(shí)号路 咨詢熱線:0716-8878286