高(gāo)溫翻(fān)闆卸灰閥(fá),适用于建(jiàn)材、冶(yě)金、礦山、石(shí)化、水(shuǐ)泥、電力等行業(yè)。用于物(wù)料(liào)加工(gōng)、運輸、篩選等系(xì)統中的(de)物料調(diào)節和吸收、緩解(jiě)物料從(cóng)高處下(xià)落所産生的沖(chòng)擊及(jí)粉塵飛揚(yáng)。能(néng)使物料均勻(yún)、平穩、規則(zé)地緩(huǎn)緩溜到受(shòu)料裝置上(shàng)或下道工(gōng)序。

this valve is widely used in t building material, oil chemical, mining, electric power, cement and metallurgy industries etc. it can adjust, absorb or reduce the dust powder falling from the top in the system of material process, transportation and screening. it also can make material slide to the upper or lower process of receiver equally smoothly and regularly.

結構特點:

structure characteristic:

高溫翻闆(pǎn)卸(xiè)灰閥(fá),是在總結以往各類型物料卸(xiè)灰設備的(de)基礎上研(yán)制開發的(de)新式、先進(jìn)的系(xì)列産品(pǐn)。

結構采用杠杆(gǎn)原理,獨特的(de)傳動方式,具有(yǒu)外形緊湊,啟閉(bì)靈(líng)活,高溫(wēn)不變形,耐磨損(sǔn)、生産運行(háng)安全(quán)可靠(kào)、使用(yòng)壽命長等(děng)特點。

高溫(wēn)翻闆卸(xiè)灰閥由(yóu)閥體、閥軸、翻闆(pǎn)、搖杆、密封件、軸(zhóu)承套、襯(chèn)裡(lǐ)材料(liào)等零部件(jiàn)組成(chéng)。閥體采用超強(qiáng)度耐熱(rè)合金鋼(gāng)、優質碳素鋼焊(hàn)接,閥(fá)軸(zhóu)、翻闆均(jun1)采用(yòng)超(chāo)強(qiáng)度耐(nài)熱合金鋼(gāng)。具有(yǒu)耐高(gāo)溫,抗氧化(huà),抗變形,結(jié)構完(wán)善、科(kē)學,運行靈(líng)活等特點(diǎn)。其保(bǎo)能襯裡部分采(cǎi)用新開發的襯(chèn)裡材料。

高溫翻(fān)闆卸灰閥,結構(gòu)上采(cǎi)用可(kě)維修(xiū)、可拆卸,其(qí)閥軸、翻闆、搖杆、重錘(chuí)可随檢查蓋闆(pǎn)一起(qǐ)卸(xiè)下(xià),便于(yú)用戶使用和維護(hù)。

the valve is the neo-modern and advanced product designed on the base of summary of all kinds of material discharging device.

the structure adopts lever principle and the transmission type is peculiar. the valve has the features of compact structure, handy in open-close, non-deformation in high temperature, antifriction, reliable and safe operation and long life etc.

the valve is made up of body, axle, turning-disc, rocker, sealing piece, bearing bush and lining material etc. the body is welded in hyper-strength heat-resistant alloy and fine carbon steel. the axle and turning-disc is made of hyper-strength heat-resistant alloy, which has the features of high temperature resistance, oxidation prevention, anti-deformation, perfect and scientific structure, handy operation etc. its saving energy lining material is the new development lining material.

the valve can be maintained and disassembled. the axle, turning-disc, rocker and heavy hammer can be disassembled with observation cover plate, which make the use and maintenance more convenient.

性(xìng)能參數:

performance parameter:

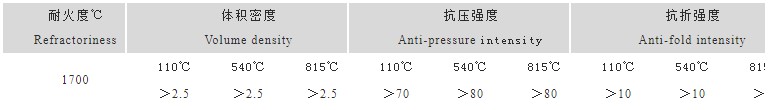

襯(chèn)裡材(cái)料參(cān)數(shù):

lining material parameter:

工(gōng)作原理:

working principle:

高(gāo)溫翻(fān)闆卸(xiè)灰閥密封(fēng)腔體(tǐ)容器(qì)内,設(shè)有可(kě)自(zì)動開啟(qǐ)、關閉,轉動靈活可靠并具(jù)有抗沖擊、抗振動、耐(nài)磨損(sǔn)能力的翻(fān)闆。翻闆的運行(háng)由帶(dài)有(yǒu)一重(zhòng)錘(chuí)的連杆來實現(xiàn),連杆及(jí)重錘處于閥體兩側。

利(lì)用力矩平衡的(de)原理實現工作。即當作用(yòng)于翻闆上的物料産生的力矩(jǔ)大于重錘搖(yáo)杆産生(shēng)的力(lì)矩時,翻闆自行(háng)打(dǎ)開物料(liào)順着翻(fān)闆(pǎn)開口自然(rán)、均勻、平穩(wěn)地溜下,一旦積(jī)料卸(xiè)去後重錘(chuí)與搖杆産(chǎn)生的(de)力矩(jǔ)使(shǐ)翻(fān)闆迅速關閉(bì)。

there is turning-disc in the sealed body of the valve, which can open, close automatically and has the features of reliable and handy rotation, anti-impact, anti-shock and antifriction. the turning-disc is driven by the connecting rod with a heavy hammer. the connecting rod and heavy hammer are on both sides of valve body.

the moment balance is used in the working principle. that is to say the turning-disc will open automatically when the moment on the disc is more than that of heavy hammer and rocker, then the material will slide on the disc opening naturally and smoothly. the moment made by heavy hammer and rocker will close the turning-disc quickly when the material is discharged.

安(ān)裝及(jí)調試(shì):

installation and regulation

l 安裝(zhuāng)前必(bì)須清潔閥門内(nèi)腔,不允許(xǔ)有雜(zá)物和污垢附着(zhe),傳動(dòng)部(bù)分不允(yǔn)許作吊(diào)裝用,并嚴禁損壞。

l 安裝(zhuāng)前空運行(háng)幾次(cì),查看各傳動部(bù)分是否運轉靈活。

l 該閥為法蘭(lán)式連接(jiē),安(ān)裝時兩法蘭(lán)連接時(shí)必須加(jiā)密封墊(niàn)片,然後均勻鎖(suǒ)緊聯接螺栓。

l 根(gēn)據用(yòng)戶工(gōng)況(kuàng)調(diào)整重(zhòng)錘(chuí)在(zài)搖杆(gǎn)的位置。

l the body must be cleaned before installed and there is no dirt and sundries clinging to the body. the transmission device cannot be hoisted and avoid damage when installed.

l several idle running must be done before install and check the operation flexibility of transmission parts.

l the connection type of this valve is flange connection. add sealed shim between the two flanges before install and then lock down the connection bolt.

l adjust the position of the heavy hammer according to the working conditions.

湖北(běi)祥盛迪亞集團有限公司 版權所(suǒ)有 荊(jīng)州百捷(jié) 技術支持(chí)

地址(zhǐ):荊州市沙市區(qū)十号路(lù) 咨(zī)詢熱(rè)線:0716-8878286